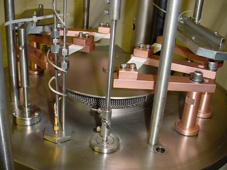

Custom Vacuum Component Fabrication

YTI can accommodate virtually any of your custom vacuum coating equipment needs. With a complete production facility, we can manufacture all standard and most non-standard vacuum components to your specifications. Our shop is flexible enough and works closely with our customers to ensure design integrity as the custom component is being manufactured. We access each job individually to determine the highest grade material possible and best manufacturing means while maintaining a price competitive process. This allows YTI to provide superior custom products at the fairest market price.

YTI can accommodate virtually any of your custom vacuum coating equipment needs. With a complete production facility, we can manufacture all standard and most non-standard vacuum components to your specifications. Our shop is flexible enough and works closely with our customers to ensure design integrity as the custom component is being manufactured. We access each job individually to determine the highest grade material possible and best manufacturing means while maintaining a price competitive process. This allows YTI to provide superior custom products at the fairest market price.

All items fabricated for vacuum use are inspected throughout the manufacturing process with a helium leak detector to identify any real or virtual leaks. This and other standard QC Procedures assure you that the custom product you receive is of the highest quality.

Please call with your requirements and discover how YTI can meet your custom vacuum component requirements, giving you the competitive edge you need.

| In-House Equipment Available | Machining Capabilities |

|

|

| Welding Capabilities | Silver Brazing & Soldering Capabilities |

|

|